Oral Solid Dosage Production Solution for Intelligent Factory

Truking Feiyun actively manages your project of oral solid dosage production from incoming materials warehousing and manufacturing, through to final products packaging and delivery, identifying the best intelligent digital solutions available. With the help of MES and SCADA software systems, our work orders, staff, materials and equipment are well controlled to assure the production compliance, thereby assisting customers in achieving intelligent production.

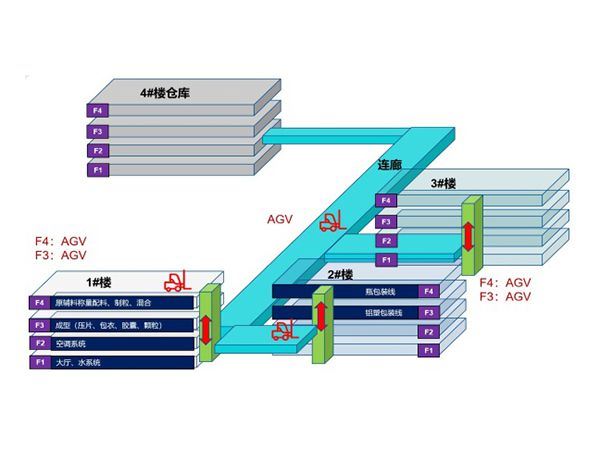

Truking Feiyun's complete production management platform framework is based on the real-time data acquisition system and the intelligent scheduling system for oral solid dosage production workshops. By monitoring all pharmaceutical processing equipment and utility facilities in the workshop, the platform performs real-time data collection, storage, supervision, centralized display and alarm activation to keep operators informed all data in a timely and accurate manner, thus achieving optimal production management, intelligent logistics scheduling and efficient batch control.

Automated guided vehicle (AGV), rail guided vehicle (RGV) and gravity transfer system are used for automated material handling and conveying. Process analytical technology (PAT) is adopted for analyzing, monitoring and controlling with the goal of ensuring the accuracy and stability of each step of the production process and providing high quality of final products. The mature PAT technology plays an essential role in the assessment of production process with accurate data support.

This approach aims at implementing information integration from planning, production to closed-loop management, including business management, compliance, and data collection.

- Complete solution of equipment and software to amplify the advantages of every machine;

- Complete solution of informatization and unmanned production for mold design and fabrication;

- Complete solution of unmanned production for products;