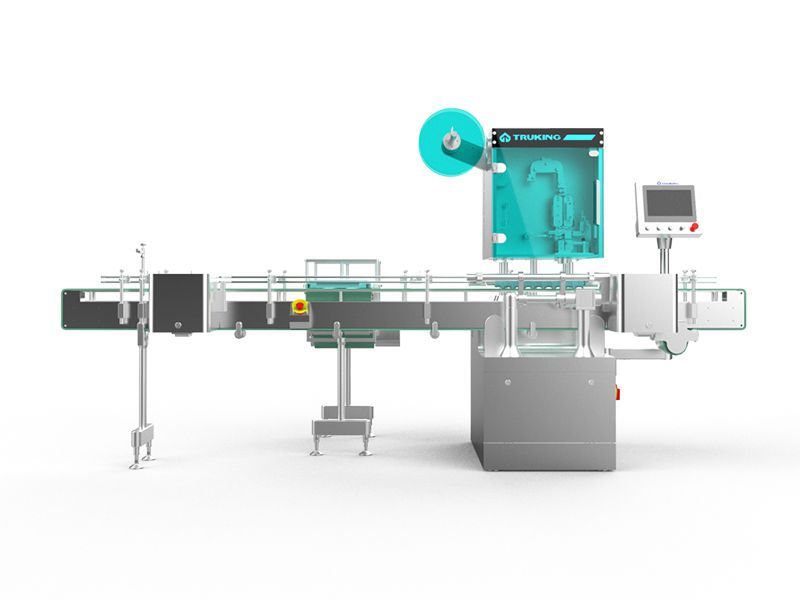

Desiccant Inserter (200 bottles/min), ISD-200

The ISD-200 desiccant inserter is used to feed the continuous strips of desiccants, desensitizers and condiments, separate them into individual packets and insert them into a variety of bottles and containers. The inserting machine is widely used in the pharmaceutical, food, supplement, candy and household chemical industries.

Features

- Automatic start and stop feeding of desiccants;

- Servo driven gripper belts for stable feeding, color mark detection for accurate positioning of desiccants;

- Servo motor controlled cutting, with dual linear guide, ensuring low noise, high speed and accurate cutting;

- During cutting, desiccants are fixed to ensure that it is cut in the right position without breaking;

- After cutting, desiccants are immediately fed and inserted into bottles in a controllable manner;

- Infeed feed screw system for quick and continuous feeding of bottles;

- Guide blocks for preventing deviation of desiccants;

- Easy changing of screw, guide block and nozzle without the use of tools, changeover takes less than 10 minutes;

- Automatic rejection of empty sachets;

- Motorized height adjustment to accommodate various bottle sizes;

- Transparent tempered glass door, stainless steel and aluminum construction, ensuring operation safety and easy cleaning;

- Human-machine operation system with 10-inch screen;

Technical Specifications

| Overall dimensions | 650mm (L)×1050mm (W)×1850mm (H) (main machine) | |

| Weight | 500kg | |

| Max. capacity | 200 bottles/min | |

| Applicable packets | Bag length: 25mm-65mm | |

| Bag width: 10mm-36mm | ||

| Continuous strips of sachet desiccant | ||

| Detection and rejection | Detection and removal of empty sachet (standard) | |

| Breakage rate | < 0.001% | |

| Pass rate | ≥99.99% | |

| Noise | ≤50dB | |

| Electric and air requirements | Main power supply | AC220 -50Hz-3-wire |

| Installation power | 1.0kW | |

| Compressed air | Quick-change adapter: Ø10mm 10L/min, (0.6MPa-0.8MPa) | |