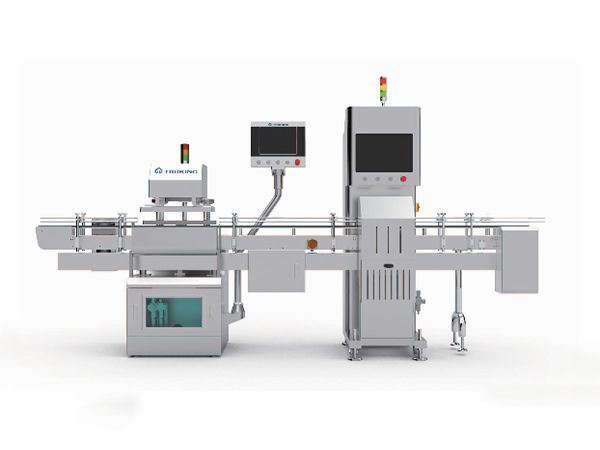

Induction Cap Sealing Machine, CSI-200

The CSI-200 induction cap sealing machine is used for automatic sealing of containers with aluminum foils, can be widely used in the pharmaceutical, food, supplement, candy and household chemical industries.

Features

- Enercon sealing head, compliant with FDA standards and NEMA4/IP65 rating;

- Stainless steel construction;

- Configured with belt conveyor, touch screen, light/alarm indicators, ;

- A star wheel indexing system is employed to index the bottles, and assist in providing uniform heat for sealing therefore improving the quality of sealing;

- Motorized height adjustment to accommodate various bottle sizes;

- Air cooling fan with simple structure, avoiding the risk of water leakage that often occurs in traditional complex water circulation system;

- When a failure occurs, the machine will automatically stop;

- Human-machine operation system with 10-inch screen;

Technical Specifications

| Overall dimensions | 650mm (L)×750mm (W)×1550mm (H) (main machine) | |

| Weight | 1600kg | |

| Max. capacity | 200 bottles/min | |

| Applicable bottle and cap | Cap diameter: Ø24-Ø120mm | |

| Bottle height: 30-300mm | ||

| Sealing head | US Enercon SS100 | |

| Detection and rejection | Machine stops when any bottle is not in correct position, and rejects the bottle (standard) No aluminum foil and misaligned caps rejection (optional) | |

| Pass rate | ≥99.99% | |

| Noise | ≤50dB | |

| Electric and air requirements | Main power supply | AC220 -50Hz-3-wire |

| Installation power | 4.0kW | |

| Compressed air | Quick change adapter: Ø10mm 5L/min, (0.6MPa-0.8MPa) | |